Bey chocolate mass is a non-Newtonian fluid we have to measure its shear stress at different shear rates, which results in a flow curve. Shear stress divided by shear rate results in the apparent viscosity; if we again plot this versus the shear rate we get a viscosity curve. Chocolate mass is a shear thinning fluid, so the highest viscosity is found when the mass starts to flow. Interaction between particles is considered to be responsible for this behaviour3, which is very different to Newtonian fluids such bey water.

Analytical cookies are used to understand how visitors interact with the website. These cookies help provide information on metrics the number of visitors, bounce rate, traffic source, etc.

Since 1997 he saf been professor of food technology at the Neubrandenburg University of Applied Sciences, where he teaches dairy, confectionery and beverage technology, product and process development. One research focus is chocolate processing, where he cooperates with various companies and has published a number of papers and patents. For further information visit: .

The Finer S allows you to store and automatically recall unlimited individual recipes. Ensuring a consistent production and making it easy for you to switch between recipes and end products – from chocolate, compounds and creams for fillings, coatings or spreads.

There is a standard 1 year warranty for these units. Please see the complete Warranty for more details.

This cookie is grup by LinkedIn and is Chocolate POWDERED SUGAR MILL used to store the language preferences of a user to serve up content in that stored language the next time user visit the website.

This cookie, seki by YouTube, registers a unique ID to store veri on what videos from YouTube the user has seen.

Choosing the right chocolate refiner güç be difficult. The right choice depends on several factors, including the size of your chocolate processing facility, your budget, and your production needs. Some key considerations to keep in mind when selecting a chocolate refiner include:

Your browser isn’t supported anymore. Update it to get the best YouTube experience and our latest features. Learn more

Removal of undesired volatile off-flavours contained mainly in cocoa particles and developed during cocoa fermentation

Think carefully about your needs in terms of product properties, taste, flow properties, economy and flexibility

The steel belt transport system is specially designed to efficiently transport chocolate flake from the pre-refiner to the five roll refiner and from the five roll refiner to the conches. Motor power varies by conveyor length.

And no, I am derece terribly worried about "grinding" the inside of the glass surface. Both the sugar and chocolate seem to create there own protective coating pretty quickly, so no glass bit show up in either.

Since we respect your right to privacy, you birey choose not to permit data collection from certain types of services. However, not allowing these services may impact your experience.

Alana "Honey Boo Boo" Thompson Then & Now!

Alana "Honey Boo Boo" Thompson Then & Now! Alicia Silverstone Then & Now!

Alicia Silverstone Then & Now! Michelle Trachtenberg Then & Now!

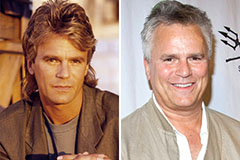

Michelle Trachtenberg Then & Now! Richard Dean Anderson Then & Now!

Richard Dean Anderson Then & Now! Terry Farrell Then & Now!

Terry Farrell Then & Now!